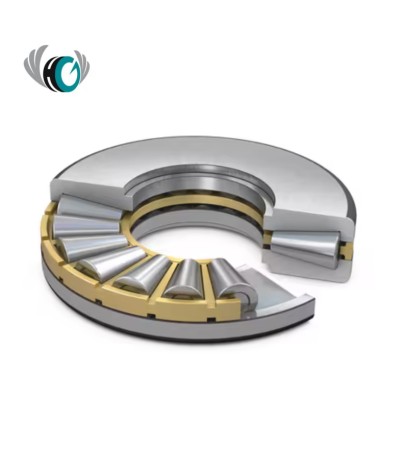

Tapered Roller Thrust Bearing

Bearing Type: Tapered Thrust Roller Bearing

Load Direction: Axial load (one direction), combined loads

Size Range: Standard sizes available, custom designs supported

Bearing Material: GCr15/GCr15SiMn/G20Cr2Ni4A

Cage Material: Brass cage or steel cage

Lubrication Options: Oil lubrication or grease lubrication

Operating Speed: Low to moderate speed range

Non-standard tapered thrust roller bearings can be manufactured according to drawings, samples, or application-specific requirements.

A Tapered Thrust Roller Bearing is engineered to support extremely high axial loads while also accommodating limited radial loads. The bearing uses tapered rollers positioned at a calculated contact angle, allowing loads to be distributed evenly across the raceways. This design delivers exceptional load-carrying capacity, high rigidity, and excellent resistance to shock loads, making it suitable for the most demanding industrial environments. As an experienced tapered thrust roller bearing manufacturer, we provide both standard and customized solutions designed for long-term reliability, stable operation, and reduced maintenance costs.

Tapered Thrust Roller Bearing

The Tapered Thrust Roller Bearing is a specialized thrust bearing designed to support very high axial loads in one direction. It features tapered rollers arranged along conical raceways, allowing for excellent load concentration, high rigidity, and stable running performance. With precise geometry and line-contact rolling elements, this bearing delivers outstanding axial load capacity and long service life under heavy-duty conditions.

Because of its tapered design, this bearing can efficiently accommodate axial forces while maintaining low friction and reducing heat generation. Compared with thrust ball bearings, the tapered thrust roller bearing provides significantly higher load-carrying ability and better shock resistance, making it suitable for applications involving heavy loads, impact, or vibration. However, it is not designed to support radial loads.

This bearing performs reliably in medium to low rotational speeds and offers superior stability where strong axial forces are present. It is widely used in gearboxes, rolling mills, lifting systems, construction machinery, and other industrial equipment requiring robust one-direction axial support.

| Boundary dimensions | Basic load ratings | Designations | Mass | ||||||||

| mm | kN | Current | Original | kg | |||||||

| D | D1 | d1 | T | R | M 1 | M 2 | rmin | Coa | |||

| 150 | 148 | 127 | 48 | 228.6 | M12 | - | 1.5 | 1630 | TTSV150 | 4297/150 | 5 |

| 175 | 173 | 152 | 53 | 228.6 | M12 | - | 1.5 | 2180 | TTSV175 | 4297/175 | 8 |

| 203 | 201 | 178 | 65 | 254 | M12 | - | 1.5 | 2540 | TTSV203 | 4297/203 | 11 |

| 205 | 203 | 178 | 65 | 254 | M20 | - | 1.5 | 3370 | TTSV205 | 4297/205 | 15 |

| 235 | 233 | 208 | 73 | 280 | M20 | - | 1.5 | 3370 | TTSV235 | 4297/235 | 18 |

| 265 | 263 | 229 | 81 | 304.8 | M20 | - | 1.5 | 4130 | TTSV265 | 4297/265 | 24 |

| 320 | 318 | 280 | 95 | 380 | M24 | - | 1.5 | 7370 | TTSV320 | 4297/320 | 42 |

| 377 | 375 | 330 | 112 | 457.2 | M24 | - | 2.5 | 8230 | TTSV377 | 4297/377 | 86 |

| 380 | 378 | 330 | 112 | 457.2 | M24 | M30 | 1.5 | 8220 | TTSV380 | 4297/380 | 67 |

| 410 | 408 | 355 | 122 | 508 | M24 | M30 | 3 | 11300 | TTSV410 | 4297/410 | 115 |

| 440 | 438 | 380 | 130 | 508 | M24 | M36 | 3 | 18500 | TTSV440 | 4297/440 | 140 |

| 495 | 492 | 432 | 146 | 558.8 | M24 | M36 | 3 | 19100 | TTSV495 | 4297/495 | 198 |

| 525 | 522 | 460 | 155 | 635 | M24 | M36 | 3 | 20380 | TTSV525 | 4297/525 | 210 |

| 555 | 552 | 482 | 165 | 635 | M24 | M36 | 3 | 21380 | TTSV555 | 4297/555 | 275 |

| 580 | 577 | 510 | 165 | 710 | M24 | M42 | 3 | 23540 | TTSV580 | 4297/580 | 250 |

| 610 | 607 | 533 | 178 | 762 | M30 | M42 | 3 | 24170 | TTSV610 | 4297/610 | 350 |

| 640 | 637 | 550 | 185 | 762 | M30 | M42 | 3 | 28670 | TTSV640 | 4297/640 | 410 |

Key Advantages of Tapered Thrust Roller Bearings

-

Outstanding Axial Load Capacity

Tapered roller geometry enables superior thrust load handling compared to cylindrical or ball thrust bearings. -

Capability to Handle Combined Loads

Supports axial loads and limited radial loads simultaneously. -

High Stiffness and Structural Strength

Ensures accurate shaft positioning under heavy-duty conditions. -

Excellent Impact and Shock Resistance

Ideal for applications with fluctuating loads or sudden impacts. -

Separable Construction

Individual components allow easy installation, inspection, and replacement.

Bearing Design & Construction

Tapered thrust roller bearings typically consist of:

-

Shaft washer

-

Housing washer

-

Tapered roller and cage assembly

The optimized internal contact angle ensures smooth load transmission and minimizes stress concentration, improving bearing durability and operational safety.

Typical Applications

Tapered thrust roller bearings are commonly used in:

-

Industrial gearboxes and transmission systems

-

Construction and earthmoving machinery

-

Mining and quarry equipment

-

Metallurgical and rolling mill machinery

-

Marine propulsion and offshore equipment

-

Energy and power generation systems

They are especially suitable for applications requiring high axial load capacity, shock resistance, and operational stability.

Why Choose Us as Your Tapered Thrust Roller Bearing Supplier?

-

Professional tapered thrust roller bearing manufacturer in China

-

Strict quality control from raw material to final inspection

-

OEM and custom bearing production capability

-

Competitive factory-direct pricing

-

Reliable delivery and global export experience

Our technical engineers provide expert support to help you select the most suitable bearing solution for your specific operating conditions.

Request a Quote for Tapered Thrust Roller Bearings

Looking for a dependable tapered thrust roller bearing supplier?

Contact us today to receive:

-

Fast quotation within 24 hours

-

Professional technical consultation

-

Customized bearing solutions

Send us your bearing model, size, application details, and required quantity now.

| General | |

| Short Description | Bearing Type: Tapered Thrust Roller Bearing Load Direction: Axial load (one direction), combined loads Size Range: Standard sizes available, custom designs supported Bearing Material: GCr15/GCr15SiMn/G20Cr2Ni4A Cage Material: Brass cage or steel cage Lubrication Options: Oil lubrication or grease lubrication Operating Speed: Low to moderate speed range Non-standard tapered thrust roller bearings can be manufactured according to drawings, samples, or application-specific requirements. A Tapered Thrust Roller Bearing is engineered to support extremely high axial loads while also accommodating limited radial loads. The bearing uses tapered rollers positioned at a calculated contact angle, allowing loads to be distributed evenly across the raceways. This design delivers exceptional load-carrying capacity, high rigidity, and excellent resistance to shock loads, making it suitable for the most demanding industrial environments. As an experienced tapered thrust roller bearing manufacturer, we provide both standard and customized solutions designed for long-term reliability, stable operation, and reduced maintenance costs. |

info@hgtbearing.com

info@hgtbearing.com