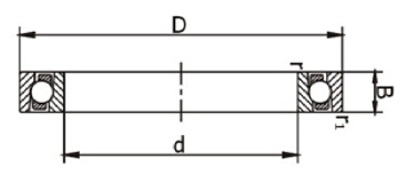

Single Row Angular Contact Ball Bearing

The single row angular contact bearings can support the axial load in one specific direction. Its axial loading capacity depends on the contact angle

The single row angular contact bearings can support the axial load in one specific direction. Its axial loading capacity depends on the contact angle α. The bigger the contact angle is, the higher its axial bearing capacity is. The typical contact angle is 15°, 25°, and 40°.

The single row angular contact bearings can support the axial load in one specific direction. Its axial loading capacity depends on the contact angle α. The bigger the contact angle is, the higher its axial bearing capacity is. The typical contact angle is 15°, 25°, and 40°.

This kind of bearing is divided into two types: separable and inseparable.

Metal solid cages are mainly used in single row angular contact ball bearings. Phenolic cloth laminated tube solid cages are usually used for high-speed applications, and the maximum temperature is 120°C.

| Boundary dimensions | Basic load ratings | Designations | Mass | Installation dimension | Limiting | ||||||||||

| mm | kN | Current | Original | kg | mm | r/min | |||||||||

| d | D | B | rmin | r1min | Cr | Cor | damin | Damax | ramax | rbmax | Grease | oil | |||

| 150 | 190 | 20 | 1.1 | 0.6 | 53.5 | 74.5 | 71830AC | - | 1.32 | 157 | 180 | 1 | 0.6 | 2400 | 3400 |

| 210 | 28 | 2 | 1 | 90 | 120 | 71930AC | - | 3 | 160 | 200 | 2 | 1 | 2400 | 3400 | |

| 225 | 35 | 2.1 | 1.1 | 153 | 130 | 7030 AC | 46130 | 4.83 | 162 | 213 | 2 | 1 | 2000 | 3000 | |

| 270 | 45 | 3 | 1.1 | 241 | 218 | 7230 AC | 46230 | 12.1 | 164 | 256 | 2.5 | 1 | 1800 | 2600 | |

| 320 | 65 | 4 | 1.5 | 360 | 375 | 7330 AC | 46330 | 25.8 | 168 | 302 | 3 | 1.5 | 1700 | 2400 | |

| 320 | 65 | 4 | 1.5 | 310 | 310 | 7330 B | 66330 | 25.8 | 168 | 302 | 3 | 1.5 | 1600 | 2200 | |

| 160 | 240 | 38 | 2.1 | 1.1 | 161 | 139 | 7032 AC | 46132 | 5.81 | 172 | 228 | 2 | 1 | 2000 | 3000 |

| 279 | 40 | 2.1 | 1.1 | 204 | 182 | - | 46932 | 11.6 | 2000 | 2800 | |||||

| 290 | 48 | 3 | 1.1 | 262 | 247 | 7232 C | 36232 | 14.5 | 174 | 283 | 2.5 | 1 | 1800 | 2600 | |

| 290 | 48 | 3 | 1.1 | 249 | 232 | 7232 AC | 46232 | 14.5 | 174 | 276 | 2.5 | 1 | 1700 | 2400 | |

| 170 | 215 | 22 | 1.1 | 0.6 | 80 | 110 | 71834C | - | 2 | 2000 | 2800 | ||||

| 230 | 28 | 2 | 1 | 110 | 140 | 71934C | - | 3.3 | 180 | 220 | 2 | 1 | 2000 | 3000 | |

| 260 | 42 | 2.1 | 1.1 | 193 | 171 | 7034 AC | 46134 | 8.25 | 182 | 248 | 2 | 1 | 2000 | 2800 | |

| 310 | 52 | 4 | 1.5 | 282 | 275 | 7234 AC | 46234 | 17.4 | 188 | 292 | 3 | 1.5 | 1600 | 2200 | |

| 310 | 52 | 4 | 1.5 | 320 | 325 | 7234 C | 36234 | 17.2 | 188 | 292 | 3 | 1.5 | 1700 | 2400 | |

| 180 | 280 | 46 | 2.1 | 1.1 | 194 | 230 | 7036 AC | 46136 | 9.8 | 192 | 268 | 2 | 1 | 1600 | 2200 |

| 320 | 52 | 4 | 1.5 | 335 | 345 | 7236 C | 36236 | 18.1 | 198 | 302 | 3 | 1.5 | 1500 | 2000 | |

| 320 | 52 | 4 | 1.5 | 315 | 325 | 7236 AC | 46236 | 18.1 | 198 | 302 | 3 | 1.5 | 1500 | 2000 | |

| 380 | 75 | 4 | 1.5 | 405 | 445 | 7336 B | 66336 | 37 | 198 | 362 | 3 | 1 | 1300 | 1800 | |

| 190 | 260 | 33 | 2 | 1 | 139 | 177 | 71938AC | 1046938 | 4.45 | 200 | 250 | 2 | 1 | 1800 | 2200 |

| 290 | 46 | 2.1 | 1.1 | 214 | 200 | 7038 AC | 46138 | 10.7 | 202 | 278 | 2 | 1 | 1600 | 2200 | |

| 340 | 55 | 4 | 1.5 | 280 | 370 | 7238B | - | 23 | 208 | 322 | 3 | 1 | 1500 | 2000 | |

| 200 | 250 | 24 | 1.5 | 1 | 90 | 130 | 71840C | - | 2.5 | 208.5 | 241.5 | 1.5 | 1 | 1800 | 2200 |

Boundary dimensions | Basic load ratings | Designations | Mass | Installation dimension | Limiting | ||||||||||

mm | kN | Current | Original | kg | mm | r/min | |||||||||

d | D | B | rmin | r1min | Cr | Cor | damin | Damax | ramax | rbmax | Grease | oil | |||

200 | 280 | 38 | 2.1 | 1.1 | 150 | 210 | 71940AC | - | 7.1 | 212 | 268 | 2 | 1 | 1600 | 2200 |

310 | 51 | 2.1 | 1.1 | 253 | 248 | 7040 AC | 46140 | 14 | 212 | 298 | 2 | 1 | 1500 | 2000 | |

360 | 58 | 4 | 1.5 | 375 | 410 | 7240 C | 36240 | 25.2 | 218 | 342 | 3 | 1.5 | 1400 | 1900 | |

360 | 58 | 4 | 1.5 | 355 | 385 | 7240 AC | 46240 | 25.2 | 218 | 342 | 3 | 1.5 | 1300 | 1800 | |

360 | 58 | 4 | 1.5 | 310 | 325 | 7240 B | 66240 | 25.8 | 218 | 342 | 3 | 1.5 | 1200 | 1700 | |

210 | 240 | 15 | 1.1 | 1.1 | 30 | 50 | 70842X3 | - | 1 | 222 | 287 | 2 | 1 | 1800 | 2200 |

220 | 300 | 38 | 2.1 | 1.1 | 200 | 250 | 71944AC | - | 7.2 | 232 | 288 | 2 | 1 | 1800 | 2200 |

400 | 65 | 4 | 1.5 | 358 | 482 | 7244 AC | 46244 | 38.5 | 1100 | 1600 | |||||

240 | 320 | 38 | 2.1 | 1.1 | 203 | 285 | 71948 C | 1036948 | 8.37 | 252 | 308 | 2 | 1 | 1200 | 1700 |

320 | 38 | 2.1 | 1.1 | 181 | 260 | 71948AC | 1046948 | 8.37 | 252 | 308 | 2 | 1 | 1100 | 1600 | |

320 | 38 | 2.1 | 1.1 | 161 | 233 | 71948 B | 1066948 | 8.43 | 252 | 308 | 2 | 1 | 1000 | 1500 | |

320 | 48 | 2.1 | 1.1 | 184 | 190 | 72948AC | 2046948 | 10 | 252 | 308 | 2 | 1 | 1100 | 1600 | |

440 | 72 | 4 | 1.5 | 420 | 490 | 7248 B | 66248 | 50.9 | 258 | 422 | 3 | 1.5 | 1000 | 1500 | |

260 | 320 | 28 | 2 | 1 | 127 | 190 | 71852AC | 1046852 | 4.85 | 270 | 310 | 2 | 1 | 1400 | 1900 |

360 | 46 | 2.1 | 1.1 | 242 | 345 | 71952AC | 1046952 | 13.5 | 272 | 348 | 2 | 1 | 1300 | 1800 | |

400 | 65 | 4 | 1.5 | 291 | 431 | 7052 B | 66152 | 28.5 | 278 | 382 | 3 | 1.5 | 1000 | 1500 | |

480 | 80 | 5 | 2 | 456 | 702 | 7252 B | 66252 | 66 | 900 | 1300 | |||||

280 | 350 | 33 | 2 | 1 | 140 | 216 | 71856AC | 1046856 | 7.2 | 290 | 340 | 2 | 1 | 1200 | 1700 |

380 | 46 | 2.1 | 1.1 | 226 | 337 | 71956AC | 1046956 | 15 | 292 | 368 | 2 | 1 | 1100 | 1600 | |

420 | 65 | 4 | 1.5 | 287 | 450 | 7056B | 66156 | 30 | 298 | 402 | 3 | 1.5 | 900 | 1400 | |

320 | 400 | 38 | 2.1 | 1.1 | 190 | 290 | 71864 | - | 10 | 332 | 388 | 2 | 1 | 800 | 1000 |

440 | 56 | 3 | 1.1 | 350 | 550 | 71964 | - | 25.5 | 334 | 426 | 2.5 | 1 | 800 | 1000 | |

340 | 460 | 56 | 3 | 1.1 | 292 | 510 | 71968 B | 1066968 | 27.5 | 354 | 446 | 2.5 | 1 | 800 | 1000 |

520 | 82 | 5 | 2 | 410 | 700 | 7068B | 66168 | 63 | 362 | 498 | 4 | 2 | 800 | 1000 | |

360 | 480 | 56 | 3 | 1.1 | 350 | 600 | 71972 | - | 29 | 374 | 466 | 2.5 | 1 | 800 | 1000 |

Boundary dimensions | Basic load ratings | Designations | Mass | Installation dimension | Limiting | ||||||||||

mm | kN | Current | Original | kg | mm | r/min | |||||||||

d | D | B | rmin | r1min | Cr | Cor | damin | Damax | ramax | rbmax | Grease | oil | |||

360 | 540 | 82 | 5 | 2 | 530 | 960 | 7072C | 36172 | 62.4 | 382 | 518 | 4 | 2 | 800 | 1000 |

540 | 82 | 5 | 2 | 468 | 855 | 7072AC | 46172 | 62.5 | 382 | 518 | 4 | 2 | 850 | 1200 | |

650 | 95 | 6 | 3 | 585 | 1125 | 7272B | 66272 | 145 | 700 | 950 | |||||

380 | 440 | 25 | 3 | 1.1 | 110 | 178 | 7676 B | 66776 | 7.1 | 960 | 1200 | ||||

480 | 31 | 2 | 1 | 171 | 310.5 | 70876AC | 7046876 | 13.5 | 850 | 1200 | |||||

480 | 46 | 2.1 | 1.1 | 261.9 | 450 | 71876AC | 1046876 | 18 | 392 | 468 | 2 | 1 | 1700 | 2400 | |

520 | 65 | 4 | 1.5 | 369 | 661.5 | 71976AC | 1046976 | 40.5 | 850 | 1200 | |||||

520 | 82 | 4 | 1.5 | 407 | 733 | 72976AC | 2046976 | 48.9 | 700 | 900 | |||||

560 | 82 | 5 | 2 | 456 | 855 | 7076AC | 46176 | 65.5 | 402 | 528 | 4 | 2 | 800 | 1100 | |

560 | 82 | 5 | 2 | 421 | 792 | 7076B | 66176 | 65.5 | 402 | 528 | 4 | 2 | 750 | 1000 | |

400 | 540 | 65 | 4 | 1.5 | 380.7 | 702 | 71980AC | 1046980 | 42 | 800 | 1100 | ||||

600 | 90 | 5 | 2 | 544.5 | 1062 | 7080AC | 46180 | 90.5 | 750 | 1000 | |||||

600 | 90 | 5 | 2 | 474 | 918 | 7080B | 66180 | 90.5 | 700 | 950 | |||||

720 | 103 | 6 | 3 | 656.2 | 1350 | 7280B | 66280 | 190 | 600 | 800 | |||||

420 | 560 | 65 | 4 | 1.5 | 380.7 | 720 | 71984AC | 1046984 | 44.5 | 434 | 546 | 2.5 | 1 | 750 | 1000 |

560 | 65 | 4 | 1.5 | 327 | 603 | 71984B | 1066984 | 44.5 | 434 | 546 | 2.5 | 1 | 700 | 950 | |

620 | 90 | 5 | 2 | 544.5 | 1062 | 7084AC | 46184 | 95 | 750 | 1000 | |||||

620 | 90 | 5 | 2 | 486 | 954 | 7084B | 66184 | 95 | 670 | 900 | |||||

440 | 600 | 74 | 4 | 3 | 456.3 | 936 | 71988AC | 1046988 | 61 | 750 | 1000 | ||||

650 | 94 | 6 | 3 | 585 | 1186 | 7088AC | 46188 | 100 | 700 | 950 | |||||

650 | 94 | 6 | 3 | 514 | 1060 | 7088B | 66188 | 100 | 468 | 622 | 5 | 2.5 | 630 | 850 | |

460 | 540 | 35 | 2.1 | 1.5 | 280 | 520 | S7692 | 6792 | 14 | 472 | 528 | 2.5 | 1 | 750 | 1000 |

580 | 37 | 2.1 | 1 | 230 | 504 | 70892AC | 7046892 | 24.5 | 474 | 566 | 2.5 | 1 | 750 | 1000 | |

580 | 56 | 3 | 3 | 334 | 689 | 71892AC | 1046892 | 34.5 | 474 | 566 | 2.5 | 1 | 750 | 1000 | |

620 | 74 | 4 | 1.5 | 456 | 936 | 71992AC | 1046992 | 58 | 850 | 1200 | |||||

Boundary dimensions | Basic load ratings | Designations | Mass | Installation dimension | Limiting | ||||||||||

mm | kN | Current | Original | kg | mm | r/min | |||||||||

d | D | B | rmin | r1min | Cr | Cor | damin | Damax | ramax | rbmax | Grease | oil | |||

480 | 600 | 56 | 3 | 1.1 | 415 | 820 | 71896 | - | 35.5 | 494 | 686 | 2.5 | 1 | 850 | 1200 |

700 | 100 | 6 | 3 | 632 | 1377 | 7096AC | 46196 | 125 | 508 | 672 | 5 | 2.5 | 630 | 850 | |

700 | 100 | 6 | 3 | 561 | 1200 | 7096B | 66196 | 125 | 508 | 672 | 5 | 2.5 | 560 | 750 | |

500 | 620 | 37 | 2.1 | 1.1 | 248 | 558 | 708/500AC | 70468/500 | 27 | 514 | 606 | 2.5 | 1 | 670 | 900 |

620 | 56 | 3 | 1.1 | 351 | 765 | 718/500 AC | 10468/500 | 38 | 514 | 606 | 2.5 | 1 | 670 | 900 | |

670 | 78 | 5 | 2 | 498 | 1098 | 719/500 AC | 10469/500 | 78 | 520 | 650 | 4 | 2 | 630 | 850 | |

720 | 100 | 6 | 3 | 644 | 1440 | 70/500 AC | 461/500 | 130 | 528 | 692 | 5 | 2.5 | 600 | 800 | |

720 | 100 | 6 | 3 | 573 | 1260 | 70/500B | 661/500 | 130 | 528 | 692 | 5 | 2.5 | 560 | 750 | |

508 | 600 | 30 | 2.1 | 1.5 | 150 | 320 | 76/508 | - | 16.5 | 670 | 900 | ||||

530 | 650 | 56 | 3 | 1.1 | 369 | 837 | 718/530AC | 10468/530 | 39.5 | 544 | 636 | 2.5 | 1 | 1100 | 1600 |

650 | 56 | 3 | 1.1 | 351 | 810 | 718/530B | 10668/530 | 39.5 | 544 | 636 | 2.5 | 1 | 630 | 850 | |

710 | 82 | 5 | 2 | 556 | 1206 | 719/530AC | 10469/530 | 92 | 552 | 688 | 4 | 2.1 | 1000 | 1500 | |

760 | 100 | 6 | 6 | 680 | 1500 | 307368B | - | 150 | 558 | 732 | 5 | 2.5 | 560 | 750 | |

780 | 112 | 6 | 3 | 813 | 1944 | 70/530AC | 461/530 | 175 | 558 | 752 | 5 | 2.5 | 560 | 750 | |

780 | 112 | 6 | 3 | 666 | 1530 | 70/530B | 661/530 | 175 | 558 | 752 | 5 | 2.5 | 500 | 670 | |

560 | 680 | 56 | 3 | 1.1 | 341 | 837 | 718/560AC | 10468/560 | 41.5 | 574 | 666 | 2.5 | 1 | 600 | 800 |

750 | 85 | 5 | 2 | 533 | 1161 | 719/560AC | 10469/560 | 105 | 582 | 728 | 4 | 2 | 560 | 750 | |

820 | 115 | 6 | 3 | 814 | 1944 | 70/560AC | 461/560 | 195 | 588 | 792 | 5 | 2.5 | 530 | 700 | |

600 | 730 | 42 | 3 | 1.1 | 304 | 662 | 708/600AC | 70468/600 | 38.5 | 614 | 716 | 2.5 | 1 | 560 | 750 |

730 | 60 | 3 | 1.1 | 421 | 1044 | 718/600AC | 10468/600 | 47 | 614 | 716 | 2.5 | 1 | 560 | 750 | |

800 | 90 | 5 | 2 | 644 | 1557 | 719/600AC | 10469/600 | 125 | 622 | 778 | 4 | 2 | 900 | 1300 | |

870 | 118 | 6 | 3 | 796 | 1944 | 70/600AC | 461/600 | 230 | 628 | 842 | 5 | 2.5 | 480 | 630 | |

670 | 820 | 69 | 4 | 1.5 | 498 | 1161 | 718/670AC | 10468/670 | 77 | 668 | 802 | 3 | 1.5 | 850 | 1200 |

980 | 136 | 7.5 | 4 | 1053 | 2790 | 70/670AC | 461/670 | 340 | 706 | 944 | 6 | 3 | 430 | 560 | |

Boundary dimensions | Basic load ratings | Designations | Mass | Installation dimension | Limiting | ||||||||||

mm | kN | Current | Original | kg | mm | r/min | |||||||||

d | D | B | rmin | r1min | Cr | Cor | damin | Damax | ramax | rbmax | Grease | oil | |||

710 | 870 | 74 | 4 | 1.5 | 546 | 1467 | 718/710AC | 10468/710 | 93.5 | 728 | 852 | 3 | 1.5 | 800 | 1100 |

950 | 106 | 6 | 3 | 767 | 1980 | 719/710AC | 10469/710 | 195 | 738 | 922 | 5 | 2.5 | 800 | 1100 | |

1030 | 140 | 7.5 | 4 | 1071 | 2925 | 70/710AC | 461/710 | 370 | 746 | 944 | 6 | 3 | 400 | 530 | |

750 | 920 | 78 | 5 | 2 | 585 | 1620 | 718/750AC | 10468/750 | 110 | 772 | 898 | 4 | 2 | 400 | 530 |

1090 | 150 | 7.5 | 4 | 1170 | 3285 | 70/750AC | 461/750 | 445 | 782 | 1054 | 6 | 3 | 360 | 480 | |

800 | 1150 | 155 | 7.5 | 4 | 1197 | 3420 | 70/800AC | 461/800 | 500 | 836 | 1114 | 6 | 3 | 340 | 450 |

850 | 1030 | 82 | 5 | 2 | 620 | 1674 | 718/850AC | 10468/850 | 140 | 872 | 1008 | 4 | 2 | 340 | 450 |

1220 | 165 | 7.5 | 4 | 1377 | 4185 | 70/850AC | 461/850 | 595 | 886 | 1184 | 6 | 3 | 300 | 400 | |

900 | 1180 | 122 | 6 | 3 | 940 | 2670 | 719/900 | - | 350 | 300 | 400 | ||||

1280 | 170 | 7.5 | 4 | 1404 | 4410 | 70/900AC | 461/900 | 665 | 936 | 1244 | 6 | 3 | 280 | 380 | |

950 | 1360 | 180 | 7.5 | 4 | 1467 | 4680 | 70/950AC | 461/950 | 805 | 986 | 1324 | 6 | 3 | 240 | 340 |

980 | 1100 | 60 | 4 | 2 | 515 | 1450 | 719/980X1 | - | 65.6 | 240 | 340 | ||||

1000 | 1220 | 100 | 6 | 3 | 831 | 2475 | 718/1000AC | 10468/1000 | 245 | 1028 | 1192 | 5 | 2.5 | 260 | 360 |

1420 | 185 | 7.5 | 4 | 1467 | 4860 | 70/1000AC | 461/1000 | 890 | 1036 | 1384 | 6 | 3 | 220 | 320 | |

1060 | 1500 | 195 | 9.5 | 5 | 1512 | 5130 | 70/1060AC | 461/1060 | 1050 | 1104 | 1456 | 8 | 4 | 200 | 300 |

1120 | 1360 | 106 | 6 | 3 | 954 | 3375 | 718/1120AC | 10468/1120 | 320 | 1148 | 1322 | 5 | 2.5 | 200 | 300 |

1580 | 200 | 9.5 | 5 | 1548 | 5265 | 70/1120AC | 461/1120 | 1150 | 1164 | 1536 | 8 | 4 | 190 | 280 | |

1140 | 1380 | 106 | 6 | 3 | 1180 | 3830 | 718/1140AC | 10468/1140 | 318 | 190 | 280 | ||||

1180 | 1660 | 212 | 9.5 | 5 | 1566 | 5580 | 70/1180AC | 461/1180 | 1350 | 1224 | 1616 | 8 | 4 | 170 | 240 |

1250 | 1500 | 80 | 6 | 3 | 725 | 2430 | 708/1250 AC | 70468/1250 | 295 | 1278 | 1472 | 5 | 2.5 | 180 | 260 |

1500 | 112 | 6 | 3 | 1026 | 3510 | 718/1250AC | 10468/1250 | 390 | 1278 | 1472 | 5 | 2.5 | 180 | 260 | |

1750 | 218 | 9.5 | 5 | 1602 | 5895 | 70/1250AC | 461/1250 | 1600 | 1294 | 1706 | 8 | 4 | 160 | 220 | |

| General | |

| Short Description | The single row angular contact bearings can support the axial load in one specific direction. Its axial loading capacity depends on the contact angle |

info@hgtbearing.com

info@hgtbearing.com