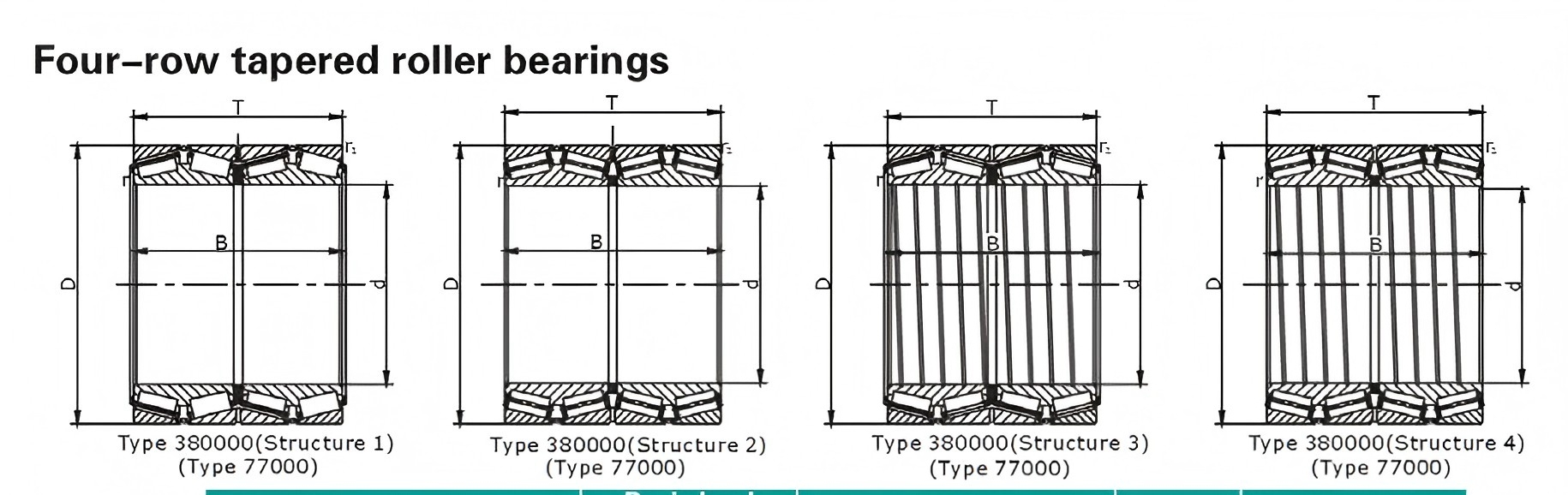

Four-row Tapered Roller Bearing

Size range: Inter diameter:120-1320mm Material: GCr15/GCr15SiMn/G20Cr2Ni4A Features: Four row tapered roller bearings are the one kind of roll neck bearings, their radial and axial loading capacity are high, can carry heavy axail loads in two directions, and their radial loading capacity is 3 times heavier than single row tapered roller bearings. Application: the working roll necks of hot or cold rolling mills, and roll neck of cogging mills. They usually clearance fit with roll necks to being mounted and dismounted conveniently. Four-row tapered roller bearings are specifically designed to withstand extremely high radial loads combined with heavy axial loads in both directions, making them an ideal solution for the most demanding industrial applications. With four rows of precision-engineered tapered rollers arranged in a compact structure, these bearings provide exceptional load distribution, outstanding rigidity, and superior resistance to shock and vibration.

Four-row tapered roller bearings are specifically designed to withstand extremely high radial loads combined with heavy axial loads in both directions, making them an ideal solution for the most demanding industrial applications. With four rows of precision-engineered tapered rollers arranged in a compact structure, these bearings provide exceptional load distribution, outstanding rigidity, and superior resistance to shock and vibration.

The optimized contact angle and precisely ground raceways ensure stable rotation, reduced friction, and reliable performance under high loads and variable operating conditions. Four-row tapered roller bearings are particularly well suited for rolling mill equipment, where continuous operation, heavy impact loads, and high accuracy are critical. Their separable design simplifies installation, inspection, and maintenance while allowing precise adjustment of internal clearance.

Manufactured from premium bearing steel with advanced heat treatment, four-row tapered roller bearings deliver long service life, high running accuracy, and consistent performance in harsh environments. Widely used in steel mills, non-ferrous metal processing, mining machinery, and large industrial gear systems, these bearings provide unmatched load-carrying capability and operational reliability for heavy-duty applications.

Technical Specifications

| Feature | Specification |

|---|---|

| Type | Four Row Tapered Roller Bearing |

| Load Rating | High radial and axial loads |

| Material | GCr15, G20Cr2Ni4A or customized materials |

| Precision Class | P0, P6, P5, P4 |

| Operating Temperature Range | -20°C to +150°C |

| Lubrication | Grease or oil lubrication |

| Customization | Size, structure, and material options available |

| Boundary dimensions | Basic load ratings | Part number | Mass | Limiting speeds | |||||||

| mm | kN | Current | Original | kg | r/min | ||||||

| d | D | T | rmin | r1min | Cr | Cor | Grease | Oil | |||

| 150 | 210 | 165 | 2.5 | 2 | 700 | 1700 | 382930 | 2077930 | 16.5 | 670 | 850 |

| 212 | 155 | 3 | 2.5 | 964 | 2350 | 30630 | - | 16.8 | 670 | 850 | |

| 160 | 220 | 165 | 2.5 | 2 | 795 | 2090 | 382932 | 2077932 | 18.5 | 670 | 850 |

| 265 | 173 | 3 | 2.5 | 1450 | 2760 | 380632 | - | 35.7 | 670 | 850 | |

| 170 | 240 | 175 | 3 | 2.5 | 1210 | 3000 | 380634 | - | 24.2 | 670 | 850 |

| 260 | 230 | 3 | 2.5 | 907 | 1720 | 382034 | 2077134 | 39.5 | 670 | 850 | |

| 180 | 250 | 185 | 2.5 | 2 | 1280 | 3400 | 382936 | - | 27.5 | 670 | 850 |

| 260 | 160 | 2.5 | 2 | 1140 | 2550 | 380636 | - | 26.7 | 670 | 850 | |

| 200 | 282 | 206 | 3 | 2.5 | 1680 | 2510 | 380640 | - | 42.1 | 560 | 700 |

| 310 | 200 | 3 | 2.5 | 1660 | 3100 | 382040X2 | 2077140 | 55.6 | 560 | 700 | |

| 310 | 275 | 3 | 2.5 | 1760 | 4200 | 382040 | 2077140 | 75.1 | 560 | 700 | |

| 205 | 320 | 205 | 3 | 3 | 1590 | 3260 | 380641 | 77741 | 57 | 500 | 630 |

| 220 | 340 | 305 | 4 | 3 | 2070 | 5430 | 382044 | 2077144 | 97.9 | 500 | 630 |

| 225 | 320 | 230 | 2.5 | 2 | 1910 | 5000 | 380645 | 77745 | 58 | 500 | 630 |

| 230 | 315 | 190 | 2.5 | 2 | 1600 | 4310 | 380646 | 77746 | 42.5 | 500 | 630 |

| 240 | 360 | 310 | 4 | 3 | 2110 | 5610 | 382048 | 2077148 | 90.5 | 450 | 560 |

| 250 | 385 | 255 | 5 | 4 | 2870 | 6450 | 381050 | 77150 | 107 | 380 | 480 |

| 260 | 360 | 265 | 3 | 2.5 | 1760 | 5220 | 382952 | 2077952 | 76.3 | 450 | 560 |

| 400 | 255 | 4 | 7.5 | 2300 | 5000 | 380652 | 77752 | 114 | 490 | 600 | |

| 400 | 345 | 5 | 4 | 2960 | 7380 | 382052 | 2077152 | 153 | 430 | 530 | |

| 440 | 300 | 2 | 5 | 3550 | 8200 | 380152 | 777752 | 164 | 450 | 560 | |

| 280 | 395 | 288 | 5 | 5 | 3051 | 8320 | 380656 | - | 108 | 450 | 560 |

| 420 | 250 | 5 | 5 | 2780 | 5700 | 380656X2 | 77756 | 119 | 450 | 560 | |

| 460 | 324 | 5 | 4 | 2840 | 7290 | 381156 | 1077756 | 200 | 360 | 450 | |

| 300 | 420 | 300 | 4 | 3 | 2330 | 7210 | 382960 | 2077960 | 130 | 380 | 480 |

| 420 | 310 | 4 | 3 | 3250 | 8150 | 380660 | 77860 | 134 | 380 | 480 | |

| 460 | 390 | 5 | 4 | 3180 | 9330 | 382060 | 2077160 | 238 | 360 | 450 | |

| 500 | 350 | 5 | 4 | 2980 | 6950 | 381160X2 | 77760 | 286 | 340 | 430 | |

| 500 | 370 | 5 | 4 | 3390 | 8710 | 381160 | 1077760 | 285 | 340 | 430 | |

| 320 | 460 | 338 | 4 | 4 | 2950 | 8200 | 380664 | 77764 | 180 | 360 | 450 |

| 460 | 380 | 4 | 4 | 3100 | 8750 | 380664X2 | 77864 | 218 | 360 | 450 | |

| 480 | 390 | 5 | 4 | 3180 | 9330 | 382064 | 2077164 | 234 | 340 | 430 | |

| 540 | 364 | 5 | 5 | 6330 | 14400 | 381164X2 | - | 347 | 340 | 430 | |

| 340 | 460 | 310 | 4 | 3 | 2480 | 8100 | 382968 | 2077968 | 145 | 340 | 430 |

| 480 | 350 | 5 | 5 | 4400 | 12600 | 380668 | - | 195 | 320 | 400 | |

| 520 | 325 | 5 | 4 | 3100 | 8620 | 381068 | 77168 | 234 | 320 | 400 | |

| 580 | 425 | 5 | 4 | 4580 | 11700 | 381168 | 1077768 | 441 | 280 | 360 | |

| 350 | 590 | 420 | 2 | 5 | 4700 | 9700 | 380670 | 77770 | 475 | 280 | 360 |

| 355 | 490 | 316 | 4 | 4 | 4520 | 12200 | 380671 | - | 115 | 320 | 400 |

| Boundary dimensions | Basic load ratings | Part number | Mass | Limiting speeds | |||||||

| mm | kN | Current | Original | kg | r/min | ||||||

| d | D | T | rmin | r1min | Cr | Cor | Grease | Oil | |||

| 360 | 480 | 310 | 4 | 3 | 2760 | 8300 | 382972 | 2077972 | 149 | 340 | 430 |

| 480 | 375 | 3 | 3 | 3010 | 7870 | 382972X2 | 77872 | 189 | 340 | 430 | |

| 520 | 370 | 4 | 4 | 5560 | 14600 | 380672 | - | 253 | 300 | 380 | |

| 540 | 325 | 5 | 4 | 3388 | 8840 | 381072 | 77172 | 248 | 300 | 380 | |

| 540 | 360 | 5 | 5 | 5070 | 12500 | 381072X2 | - | 274 | 300 | 380 | |

| 600 | 420 | 6 | 6 | 7900 | 14000 | 381172 | 1077772 | 388 | 280 | 360 | |

| 600 | 540 | 5 | 5 | 9970 | 24900 | 381172X2 | - | 620 | 240 | 360 | |

| 370 | 490 | 292 | 3 | 3 | 3800 | 11600 | 380674 | - | 149 | 340 | 430 |

| 380 | 520 | 400 | 4 | 3 | 5560 | 16100 | 380676 | - | 240 | 280 | 380 |

| 550 | 350 | 5 | 5 | 5250 | 13100 | 380676 | 77776 | 273 | 280 | 380 | |

| 560 | 325 | 5 | 4 | 3360 | 8840 | 381076 | 77176 | 281 | 280 | 380 | |

| 560 | 360 | 5 | 5 | 5730 | 14000 | 381076X2 | - | 294 | 280 | 360 | |

| 620 | 388 | 6 | 6 | 4200 | 9500 | 381176X2 | 3077776 | 443 | 240 | 360 | |

| 620 | 420 | 5 | 4 | 4710 | 12300 | 381176 | 1077776 | 519 | 240 | 360 | |

| 395 | 545 | 288.7 | 4 | 7.5 | 2610 | 7490 | 380679 | 77779 | 194 | 280 | 360 |

| 400 | 540 | 280 | 4 | 4 | 3100 | 8750 | 380680 | 77880 | 175 | 280 | 360 |

| 600 | 356 | 5 | 4 | 4160 | 10400 | 381080 | 77180 | 317 | 240 | 320 | |

| 420 | 620 | 356 | 5 | 4 | 4160 | 10400 | 381084 | 77184 | 358 | 220 | 300 |

| 700 | 480 | 6 | 5 | 6780 | 18500 | 381184 | 1077784 | 760 | 190 | 260 | |

| 760 | 500 | 7.5 | 7.5 | 9350 | 20300 | 380684 | 77884 | 1039 | 180 | 240 | |

| 440 | 620 | 454 | 6 | 6 | 3960 | 7880 | 380688 | 77888 | 440 | 200 | 280 |

| 650 | 355 | 6 | 6 | 4290 | 12390 | 380088 | 77788 | 385 | 200 | 280 | |

| 650 | 376 | 6 | 5 | 4330 | 13700 | 381088 | 77188 | 401 | 200 | 280 | |

| 460 | 620 | 310 | 4 | 3 | 3360 | 10200 | 381992 | 1077992 | 232 | 200 | 280 |

| 650 | 474 | 6 | 6 | 5292 | 11270 | 380692 | 77892 | 495 | 180 | 240 | |

| 680 | 410 | 6 | 5 | 5130 | 14200 | 381092 | 77192 | 476 | 180 | 240 | |

| 730 | 440 | 4 | 7.5 | 6500 | 15100 | 380692X3 | 77792 | 694 | 170 | 220 | |

| 475 | 660 | 450 | 5 | 5 | 7330 | 22400 | 380695 | 77795 | 457 | 170 | 220 |

| 480 | 650 | 338 | 5 | 4 | 2450 | 5400 | 381996 | 1077996 | 301 | 190 | 260 |

| 678 | 494 | 6 | 6 | 10600 | 31900 | 380696 | - | 578 | 170 | 220 | |

| 700 | 342 | 6 | 6 | 7050 | 17900 | 381096X2 | - | 447 | 170 | 220 | |

| 700 | 420 | 6 | 5 | 5780 | 16900 | 381096 | 77196 | 547 | 170 | 220 | |

| 790 | 510 | 7.5 | 7.5 | 11570 | 26900 | 381196X2 | - | 1017 | 120 | 160 | |

| 490 | 625 | 385 | 4 | 4 | 5070 | 17670 | 380698 | - | 282 | 170 | 220 |

| 500 | 720 | 420 | 6 | 5 | 6650 | 19400 | 3810/500 | 771/500 | 565 | 160 | 200 |

| 830 | 540 | 7.5 | 7.5 | 13230 | 33000 | 3811/500X2 | - | 1194 | 120 | 160 | |

| 508 | 762 | 420 | 6 | 6 | 9050 | 23900 | 3806/508 | - | 684 | 160 | 200 |

| 520 | 735 | 535 | 6 | 6 | 10580 | 33400 | 3806/520 | - | 721 | 160 | 200 |

| 530 | 780 | 450 | 6 | 5 | 7520 | 21500 | 3810/530 | 771/530 | 744 | 140 | 180 |

| 870 | 560 | 7.5 | 7.5 | 14400 | 36150 | 3811/530X2 | - | 1342 | 120 | 160 | |

| 870 | 590 | 7.5 | 6 | 9300 | 26100 | 3811/530 | 10777/530 | 1422 | 120 | 160 | |

| 880 | 544 | 7.5 | 7.5 | 10500 | 25600 | 3806/530 | 30777/530 | 1350 | 120 | 160 | |

| 540 | 690 | 400 | 5 | 5 | 4860 | 17300 | - | 779/540 | 375 | 160 | 200 |

| 560 | 730 | 410 | 4 | 6 | 5560 | 18900 | 3828/560X | - | 441 | 140 | 180 |

| Boundary dimensions | Basic load ratings | Part number | Mass | Limiting speeds | |||||||

| mm | kN | Current | Original | kg | r/min | ||||||

| d | D | T | rmin | r1min | Cr | Cor | Grease | Oil | |||

| 560 | 750 | 368 | 5 | 4 | 4370 | 13300 | 3819/560 | 10779/560 | 456 | 140 | 180 |

| 920 | 620 | 7.5 | 6 | 11200 | 26100 | 3811/560 | 10777/560 | 1635 | 100 | 140 | |

| 600 | 800 | 365 | 5 | 5 | 5000 | 17800 | - | 779/600 | 489 | 120 | 160 |

| 800 | 380 | 5 | 4 | 5500 | 18900 | 3819/600 | 10779/600 | 536 | 120 | 160 | |

| 855 | 620 | 6 | 6 | 14700 | 48100 | 3806/600 | - | 1155 | 100 | 140 | |

| 870 | 415 | 6 | 6 | 9790 | 27200 | 3810/600X2 | - | 831 | 100 | 140 | |

| 870 | 480 | 6 | 5 | 8370 | 25400 | 3810/600 | 771/600 | 995 | 100 | 140 | |

| 980 | 615 | 7.5 | 6 | 17600 | 45600 | 3811/600X2 | - | 1865 | 90 | 120 | |

| 980 | 650 | 7.5 | 6 | 12700 | 36700 | 3811/600 | 10777/600 | 1970 | 90 | 120 | |

| 625 | 815 | 480 | 5 | 5 | 10400 | 31700 | 3806/625 | 777/625 | 647 | 100 | 140 |

| 630 | 850 | 418 | 6 | 5 | 6440 | 19800 | 3819/630 | 10779/630 | 720 | 100 | 140 |

| 890 | 650 | 7.5 | 7.5 | 16970 | 53800 | 3806/630 | - | 1293 | 100 | 140 | |

| 920 | 515 | 7.5 | 6 | 9170 | 26800 | 3810/630 | 771/630 | 1158 | 95 | 130 | |

| 920 | 600 | 7.5 | 7.5 | 16500 | 48200 | 3810/630X2 | - | 1342 | 90 | 120 | |

| 1030 | 645 | 7.5 | 7.5 | 20270 | 53160 | 3811/630X2 | - | 2162 | 85 | 110 | |

| 1030 | 670 | 7.5 | 6 | 14400 | 39900 | 3811/630 | 10777/630 | 2170 | 85 | 110 | |

| 650 | 1030 | 560 | 7.5 | 12 | 11460 | 22050 | 3806/650 | 777/650 | 1769 | 85 | 110 |

| 660 | 1070 | 650 | 7.5 | 7.5 | 12600 | 26500 | 3806/660 | 777/660 | 2282 | 80 | 100 |

| 670 | 900 | 412 | 6 | 5 | 6940 | 22300 | 3819/670 | 10779/670 | 959 | 95 | 130 |

| 950 | 700 | 7.5 | 7.5 | 19800 | 61900 | 3806/670 | - | 1599 | 90 | 120 | |

| 980 | 475 | 7.5 | 7.5 | 13880 | 36500 | 3810/670X2 | - | 1224 | 90 | 120 | |

| 1090 | 690 | 7.5 | 7.5 | 22700 | 58800 | 3811/670X2 | - | 2566 | 75 | 95 | |

| 1090 | 710 | 7.5 | 6 | 15700 | 39900 | 3811/670 | 10777/670 | 2665 | 75 | 95 | |

| 710 | 1030 | 490 | 7.5 | 7.5 | 14500 | 40600 | 3810/710X2 | - | 1372 | 75 | 95 |

| 1030 | 555 | 7.5 | 6 | 11200 | 35800 | 3810/710 | 771/710 | 1568 | 75 | 95 | |

| 1150 | 710 | 9.5 | 8 | 24500 | 65000 | 3811/710X2 | - | 2931 | 48 | 80 | |

| 1150 | 750 | 9.5 | 8 | 15840 | 33960 | 3811/710 | 10777/710 | 3227 | 48 | 80 | |

| 730 | 1035 | 755 | 7.5 | 7.5 | 22500 | 73200 | 3806/730 | - | 2043 | 75 | 95 |

| 750 | 1090 | 515 | 7.5 | 6 | 16200 | 45600 | 3810/750X2 | - | 1619 | 70 | 90 |

| 1090 | 605 | 7.5 | 6 | 13100 | 42400 | 3810/750 | 771/750 | 1874 | 70 | 90 | |

| 1130 | 690 | 7.5 | 7.5 | 19000 | 51700 | 3806/750 | 777/750 | 2516 | 48 | 80 | |

| 1220 | 750 | 9.5 | 8 | 27430 | 7380 | 3811/750X2 | - | 3504 | 48 | 80 | |

| 1220 | 840 | 9.5 | 8 | 21900 | 68000 | 3811/750 | 10777/750 | 3994 | 48 | 80 | |

| 774 | 1130 | 690 | 4 | 7.5 | 16700 | 50100 | - | 777/774 | 2400 | 48 | 80 |

| 780 | 1220 | 840 | 9.5 | 8 | 28400 | 74000 | 3806/780 | 779/780 | 3659 | 48 | 80 |

| 800 | 1120 | 820 | 7.5 | 7.5 | 26200 | 86300 | 3806/800 | - | 2842 | - | - |

| 840 | 1170 | 840 | 7.5 | 7.5 | 26300 | 86400 | 3806/840 | - | 2840 | - | - |

| 850 | 1360 | 900 | 12 | 9.5 | 38900 | 140600 | 3811/850 | 10777/850 | 5168 | - | - |

| 950 | 1360 | 880 | 7.5 | 6 | 23300 | 83600 | 3820/950 | 20771/950 | 4087 | - | - |

| 1060 | 1500 | 1000 | 9.5 | 8 | 29100 | 105000 | 3820/1060 | 20771/1060 | 5698 | - | - |

| 1070 | 1400 | 889.762 | 4 | 12 | 27270 | 90000 | BT4B 328100 | - | 3730 | - | - |

| 1080 | 1450 | 950 | 5 | 12 | 30240 | 97200 | BT4B 331559 | - | 4450 | - | - |

| 1250 | 1550 | 890 | 5 | 12 | 27270 | 102600 | BT4B 328819 | - | 3820 | - | - |

| 1260 | 1640 | 1000 | 5 | 12 | 35190 | 128700 | BT4B 332124 | - | 5800 | - | - |

| 1300 | 1720 | 1040 | 5 | 12 | 38610 | 126000 | BT4B 331950 | - | 7000 | - | - |

| 1500 | 1900 | 1080 | 4 | 12 | 42120 | 153000 | BT4B 332078 | - | 7700 | - | - |

| 1580 | 1960 | 1080 | 5 | 12 | 41130 | 158400 | BT4B 331934 | - | 7800 | - | - |

| General | |

| Short Description | Size range: Inter diameter:120-1320mm Material: GCr15/GCr15SiMn/G20Cr2Ni4A Features: Four row tapered roller bearings are the one kind of roll neck bearings, their radial and axial loading capacity are high, can carry heavy axail loads in two directions, and their radial loading capacity is 3 times heavier than single row tapered roller bearings. Application: the working roll necks of hot or cold rolling mills, and roll neck of cogging mills. They usually clearance fit with roll necks to being mounted and dismounted conveniently. Four-row tapered roller bearings are specifically designed to withstand extremely high radial loads combined with heavy axial loads in both directions, making them an ideal solution for the most demanding industrial applications. With four rows of precision-engineered tapered rollers arranged in a compact structure, these bearings provide exceptional load distribution, outstanding rigidity, and superior resistance to shock and vibration. |

info@hgtbearing.com

info@hgtbearing.com