Understanding Angular Contact Ball Bearings: Structure, Preload, and Mounting Configurations

Angular contact ball bearings are one of the most widely used bearing types, known for their excellent speed performance and high load-carrying capacity. Compared with deep groove ball bearings, they can support both radial and axial loads, making them ideal for high-speed and high-precision applications. However, due to their internal geometry, a single angular contact bearing can only withstand axial load in one direction, which requires special consideration in design and installation.

Structure and One-Directional Load Capacity

As shown in the diagram below (illustrative), the internal structure of an angular contact ball bearing defines its axial load direction — it can only bear load from the inner ring’s thick side toward the outer ring’s thick side.

If the axial load acts in the opposite direction, the bearing tends to separate, preventing pure rolling of the balls. This may lead to excessive friction, heat generation, and premature failure.

The Necessity of Axial Preload

To prevent the occurrence of reverse axial load and maintain stability, axial preload must be applied to the bearing.

Preload eliminates internal clearance, ensures correct contact between rolling elements and raceways, and improves rigidity and running accuracy.

Single Bearing Preload

For a single angular contact ball bearing, preload should be applied in the direction of its axial load capacity (from the outer ring’s thick side to the inner ring’s thick side).

Determining the Preload Value

The preload value should exceed the maximum expected reverse axial load to ensure the bearing always operates under positive internal load. It must also satisfy the minimum bearing load requirement, ensuring proper rolling motion under all operating conditions.

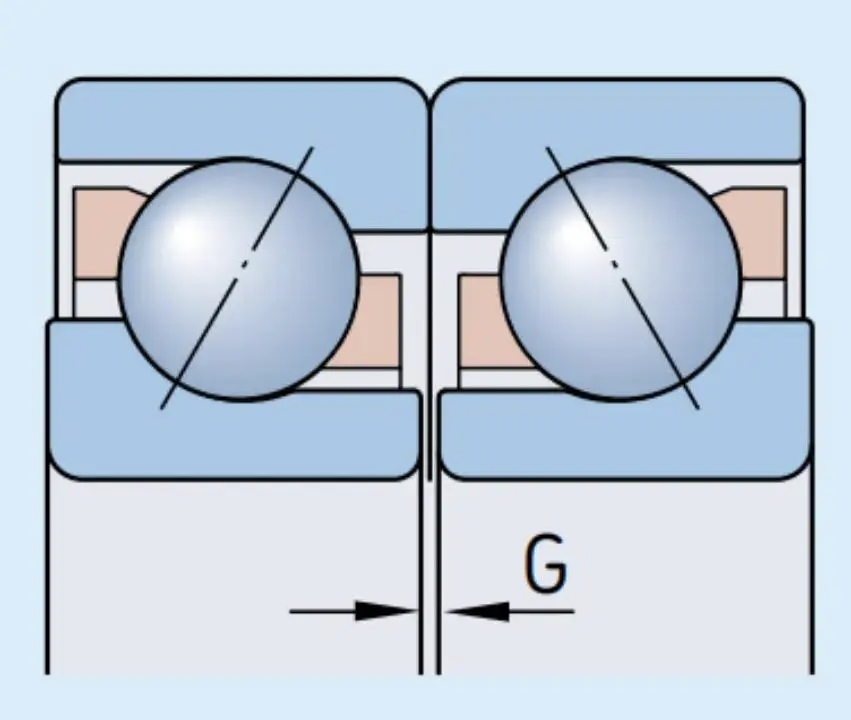

Paired Angular Contact Bearings (Face-to-Face / Back-to-Back)

To accommodate axial loads in both directions, angular contact ball bearings are often installed in pairs, either:

Back-to-back (DB) – outer ring thick sides face each other

Face-to-face (DF) – outer ring thin sides face each other

In both configurations, each bearing supports axial load in one direction.

For example, in a back-to-back arrangement, the left bearing carries rightward axial load, while the right bearing carries leftward load.

This setup typically provides axial stiffness in both directions and doesn’t require external axial preload to maintain position.

Applying Preload in Paired Bearings

Even though paired bearings can balance axial loads, preload can still be applied to improve rigidity and reduce operational vibration.

In back-to-back configurations, when both thick sides are pressed together, a small gap remains between the thin sides.

If an external force eliminates this gap, the bearing set enters a negative internal clearance state—that is, preload is generated.

Manufacturers precisely control this preload through dimensional matching (pairing) of the thick and thin ring sides during production, ensuring optimal assembly preload after mounting.

Spacer-Controlled Bearing Arrangements

In some applications, such as machine tool spindles or gearboxes, two back-to-back angular contact bearings may be installed at opposite ends of a shaft, separated by a spacer.

Here, the spacer length determines preload:

A longer spacer increases preload

A shorter spacer reduces it

The final working clearance or preload is influenced by:

Spacer dimensions

Shaft and housing fits (thermal expansion differences)

Operating temperature variations

Proper preload ensures that the non-loaded bearing always maintains internal contact without separation under any operating condition.

Application Considerations

In industrial motors, pre-paired and preloaded bearing units are often supplied directly by the manufacturer, simplifying assembly.

In gearbox and precision machinery applications, preload must be carefully calculated and adjusted to achieve optimal performance and longevity.

Conclusion

The correct design and application of angular contact ball bearings require a deep understanding of load direction, preload management, and installation geometry.

Whether for high-speed motors, gearboxes, or precision machinery, HGT Bearing provides customized bearing solutions with optimized preload control to ensure stability, accuracy, and extended service life.

info@hgtbearing.com

info@hgtbearing.com