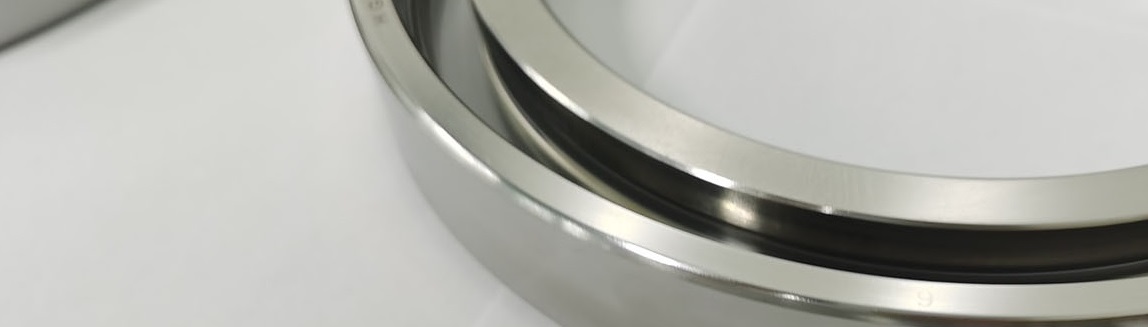

Components of bearings for inspecting semiconductor equipment/an example for custom-production

As a professional research firm and experienced manufacturer, we can carry special research projects in bearing or OEM production, either bearing or its components.

An example of how we work closely with our customers.

Design phase: The customer requires light bearings with P4 above precision grade, preload, axial and radial loads, and cleanliness within four months.

1. Meeting with our customers through zoom meeting and understanding the actual requirements.

2. A technical team formed in our company work with the client’s technical team.

3. Suggestion from our team: Using ceramic balls instead of metal balls to reduce the weight and stainless-steel rings are recommended.

4. Bearing’s components cleaned and double vacuum sealed for shipping

5. We prioritized this production after the customer validated the designs.

Service phase:

6. Installation phase: Design a bearing installation tooling for the customer to assemble bearing components in their clean, dust-free workshop. This is the only way customer can get the super clean bearings for their application.

Shipping phase:

7. Calculate the permissible shock loading G-force and recommend the lock mechanism before shipping.

Please don’t hesitate to contact us at info@hgtbearing.com if you have any demands.

info@hgtbearing.com

info@hgtbearing.com